AKS Technology

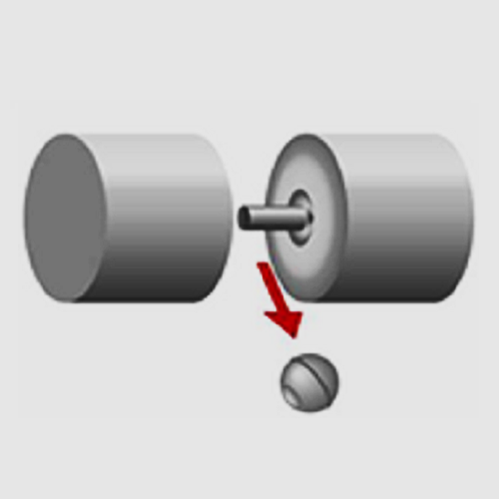

To make one ball, wire needs to be cut at required length

and each piece compressed

into sphere/ball shape by pair of dies.

Shape of molded ball

with the band still attached.

Flashing

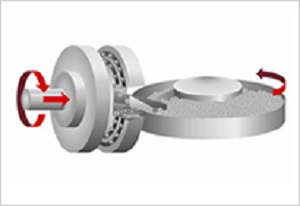

By using two grooved boards,

a number of balls that have been formed are processed one by one.

The ball is ground while rotating and pressed to remove the ‘belt’.

Then, be a ball of a certain size.

Heat Treatment

Balls are quenched and tempered to give them sufficient strength and durability.diinginkan

Grinding

Being Pressed and Grinded

With 2 grooved boards, predetermined number of molded balls are being pressed and grinded while rotating one after another. And the balls are finished with specified size.

Level of Roughness

Processing method is the same as previous process, GRINDING process. Each process we change the material of board. And when the ball finished with specified size, at the same time the surface roughness and size accuracy also being improved to get specular finish ball.

First Lapping

Shape of ball after first lapping process.

Second Lapping

Shape of ball after second lapping process.

Visual Inspection

We perform automatic visual inspection by machine to decide quality of products.

Packing

Balls that passed visual inspection are treated with anti-corrosive oil and then packed in paperboard boxes.